Product Brief

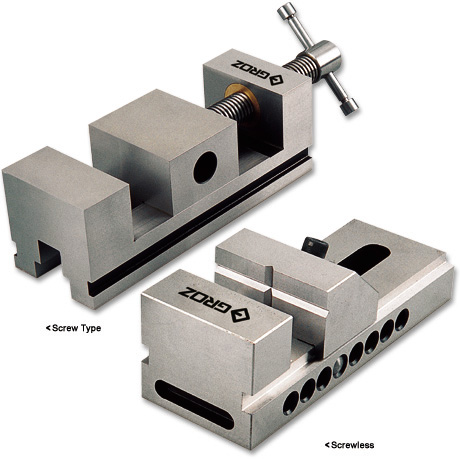

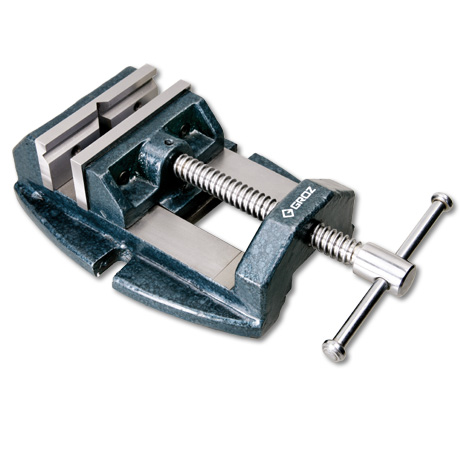

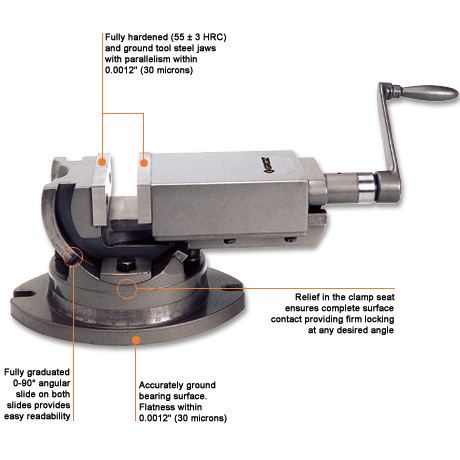

Manufactured from selected tool steel, these solid one piece vices are fully hardened (55-60 HRC) and tempered to ensure stability and durability

All vice surfaces are precision ground

The movable jaw is narrower than the base enabling vices to be used on either sides in addition to the base

Due to their outstanding accuracies, these vices are mainly used in tool manufacturing, on grinding & milling machines, in engraving & jig boring applications, for measurement and inspection work and in manufacturing process that require highest standards of clamping accuracy

These are available in two models:

Screwless Type

The rapid positioning notches allow the vice to be locked in any position by means on an allen key provided with the vice

Vee grooves in the sliding jaw, both horizontal and vertical, facilitate holding of round jobs. Jaw pressure on work piece is forward and downward for repeatable positioning and maximum holding power These vices are particularly suitable for erosion work

Screw Type

Clamping and releasing is through a threaded spindle with precision cut square threads for smooth operation

Vice spindle moves in a specially designed gun metal bush which reduces wear this enhancing life of the vice.

Ordering Information

| Cat. Nr. | Ordering Nr. | Jaw Width | Jaw Opening | Jaw Depth | Net Wt. Each | |||||||||||||||

| inch | mm | inch | mm | Inch | mm | Kg. | ||||||||||||||

| Screwless Type | ||||||||||||||||||||

TMV/2 TMV/2 |

35200 | 2 | 50 | 3-17/32 | 90 | 1 | 25 | 1.800 | ||||||||||||

TMV/23 TMV/23 |

35201 | 3 | 75 | 4-5/16 | 110 | 1-3/8 | 35 | 3.500 | ||||||||||||

| Screw Type | ||||||||||||||||||||

TMV/ST/4 TMV/ST/4 |

35205 | 2-3/4 | 70 | 3 | 75 | 1-9/16 | 40 | 4.900 | ||||||||||||

|

||||||||||||||||||||

| Accuracies | Guaranteed | Actual Average | ||||||||

| inch | Micron | inch | Micron | |||||||

| Flatness of bearing surface | 0.00031" | 8 | 0.00019" | 5 | ||||||

| Parallelism of slide face & top to bottom face | 0.00031" | 8 | 0.00019" | 5 | ||||||

| Squareness of slides & slide faces | 0.00047" | 12 | 0.00031" | 8 | ||||||

| Parallelism of slides & slide ways | 0.00031" | 8 | 0.00019" | 5 | ||||||

| Squareness 0f fixed jaw back to bottom surface & sides | 0.00047" | 12 | 0.00031" | 8 | ||||||

| Parallelism of fixed jaw & Length faces | 0.00031" | 8 | 0.00019" | 5 | ||||||

| Parallelism of jaw faces | 0.00031" | 8 | 0.00019" | 5 | ||||||

| Sliding jaw square to bottom face when vice Is clamped | 0.00047" | 12 | 0.00031" | 8 | ||||||

| Sliding jaw face parallel when vice is clamped | 0.00031" | 8 | 0.00019" | 5 | ||||||

.jpg)